DED Technology

DED Technology

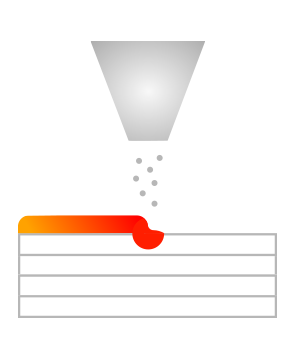

The DED process moves a deposition head in 3D space, supplying metal inpowder or wire form and using a high-energy heat source such as an arc or

laser to rapidly melt and solidify the material for creating 3D shapes.

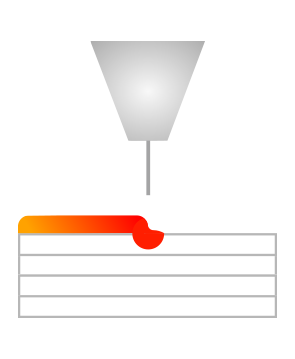

Laser-Powder

Laser Powder : 0.6kW

Build Rate : 0.2kg/h

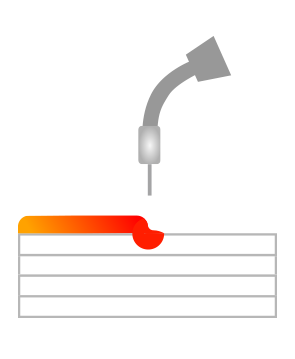

Laser-Wire

Laser Powder : 1.4kW

Build Rate : 0.8kg/h

Arc-Wire

Arc : 350A

Build Rate : 3kg/h

* The stated information may vary depending on the equipment, materials, and operating conditions.

Comparison

The DED process is categorized into detailed technologies based on the metal deposition method, each possessing distinct strengths. Optimal solutions can be selected according to the customer’s industry and application.

- Laser-Powder

-

- Material: Metal powder

- Heat source: Laser

- Surface quality/precision: Good

- Manufacturing speed: Slow

- Manufacturing cost: High

- Applications: Research on dissimilar materials, coating, cladding, and other metal materials

- Laser-Wire

-

- Material: Metal wire

- Heat source: Laser

- Surface quality/precision: Good

- Manufacturing speed: Moderate

- Manufacturing cost: Moderate

- Applications: Aerospace, energy, defense, etc.

- Arc-Wire

-

- Material: Metal wire

- Heat source: Arc

- Surface quality/precision: Rough

- Manufacturing speed: Fast

- Manufacturing cost: Low

- Applications: Marine, heavy industry, construction, etc.

Related AM Systems