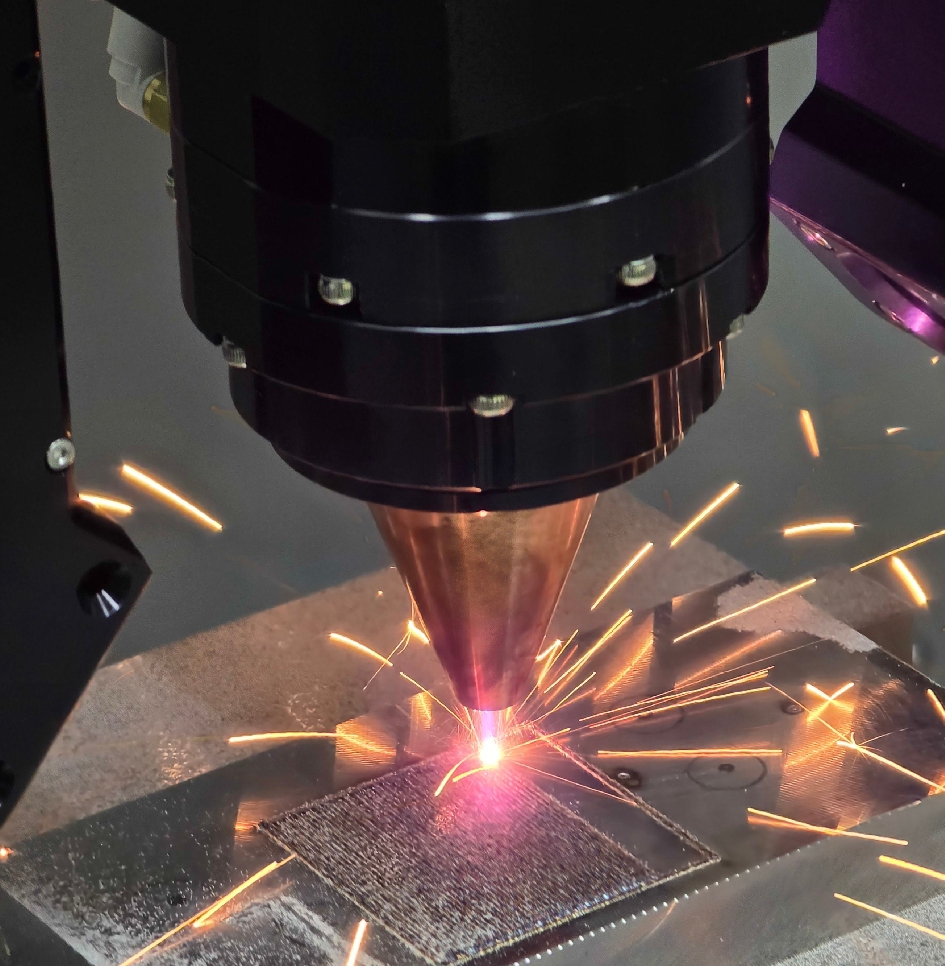

AM Solutions’ powder-based DED system is an advanced metal 3D printing technology that utilizes a high-power laser to create a localized molten pool on the metal surface, while precisely feeding metal powder to build up new metallic layers.

The powder DED process enables the flexible formation of metal components with various geometries and offers broad applicability ranging from fundamental research to advanced applications, including material experimentation, process optimization, and the fabrication and repair of complex parts.

A diverse lineup of Powder DED equipment is available,

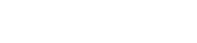

POWDER DED SYSTEM

This high-performance powder DED system is designed for R&D applications involving freeform 3D deposition. Its stable 3-axis motion structure makes it well-suited for linear and planar deposition processes.

The built-in smart platform enables real-time monitoring and control of powder feed rate, shielding gas flow, nozzle/lens temperature, and oxygen and humidity levels within the chamber. This allows for precise process control and high reproducibility, establishing the system as a dedicated research-grade solution.

It is an ideal system for fundamental research on additive processes, evaluation of metal material properties, and accumulation of experimental data based on process parameters.

XYZ

A/C

Robot

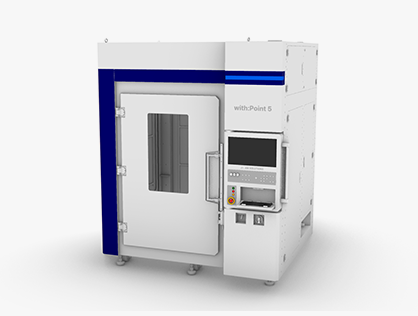

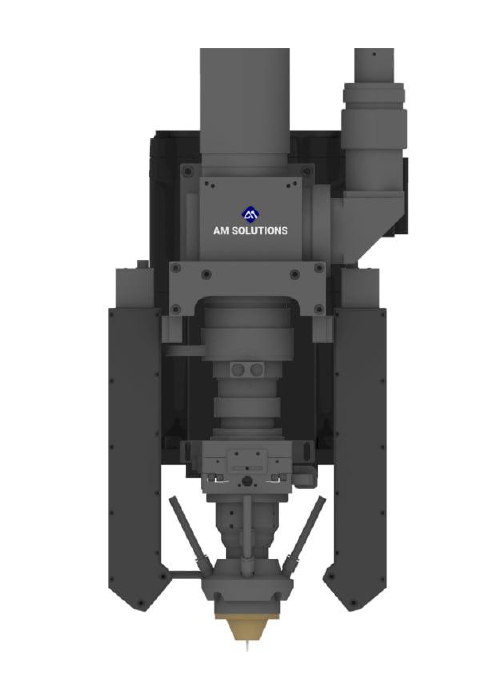

POWDER DED SYSTEM

It adopts a 5-axis simultaneous control structure by combining rotational axes (A, B, or C) with the X, Y, and Z axes, enabling uniform deposition thickness and shape even on curved and inclined surfaces.

Through precise localized melting control using a high-power laser and flexible process orientation enabled by rotational axes, this system is optimized for complex 3D shape fabrication, irregular part manufacturing, and high-precision repair.

It provides a powerful solution for the fabrication and refurbishment of high-complexity components required across various industries.

XYZ

A/C

Robot

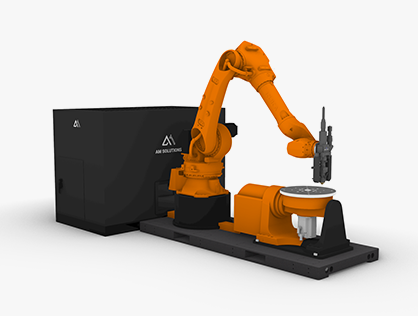

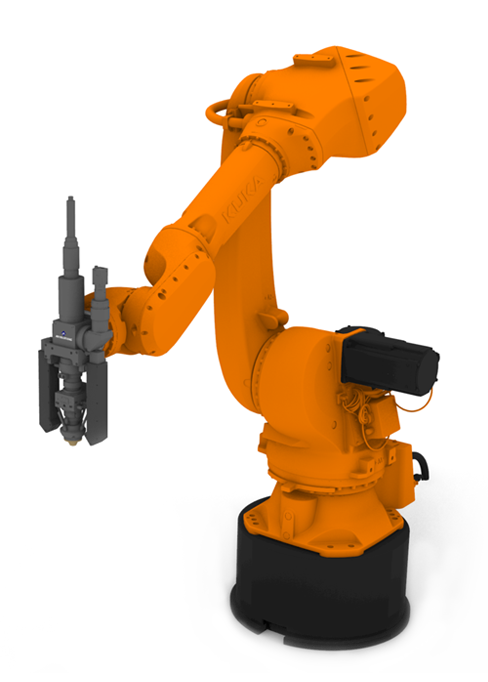

POWDER DED SYSTEM

This system integrates a high-power DED head with an industrial 6-axis robot, offering highly flexible deposition path control and adaptable accessibility for large-scale components.

This system enables deposition on surfaces that are difficult to achieve with fixed equipment, such as curved, vertical, inclined, and internal geometries. By leveraging the multi-joint flexibility of the robot, it allows for on-site operations including localized repair, large-scale metal structure fabrication, and curved surface cladding.

In particular, it is advantageous for configuring additive manufacturing cells in conjunction with large equipment or existing facilities, making it well-suited as an on-site solution for shipyards, power plants, and the defense industry.

XYZ

A/C

Robot

Designed to meet your unique requirements

| 3-Axis Powder DED System | 5-Axis Powder DED System | |

|---|---|---|

| X, Y, Z axes | Axes Configuration | X, Y, Z + 2 rotational axes (A, B or C) |

| Suitable for simple and planar structures | Geometry Capability | Capable of complex freeform geometries such as curved or inclined surfaces |

| Material testing, process optimization, basic research | Application Areas | Complex shape fabrication, curved surface repair, high-value part production |

| Basic structure with precise linear motion | System Structure | Hybrid processing based on multi-axis control |

| Relatively simple | System Complexity | Highly integrated mechatronic system |

| Standard integrated control platform | Control System | Advanced smart additive control platform |

| Material property research, deposition process testing | Example Use Cases | Precision parts such as aerospace components and turbine blades |

| Early-stage R&D institutions and universities | Target Users | Advanced research institutes, industrial users, and production process optimization |