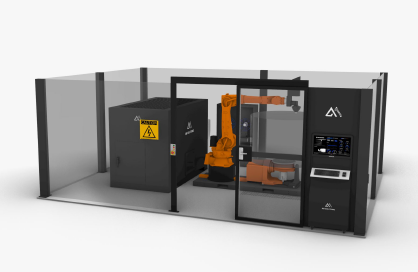

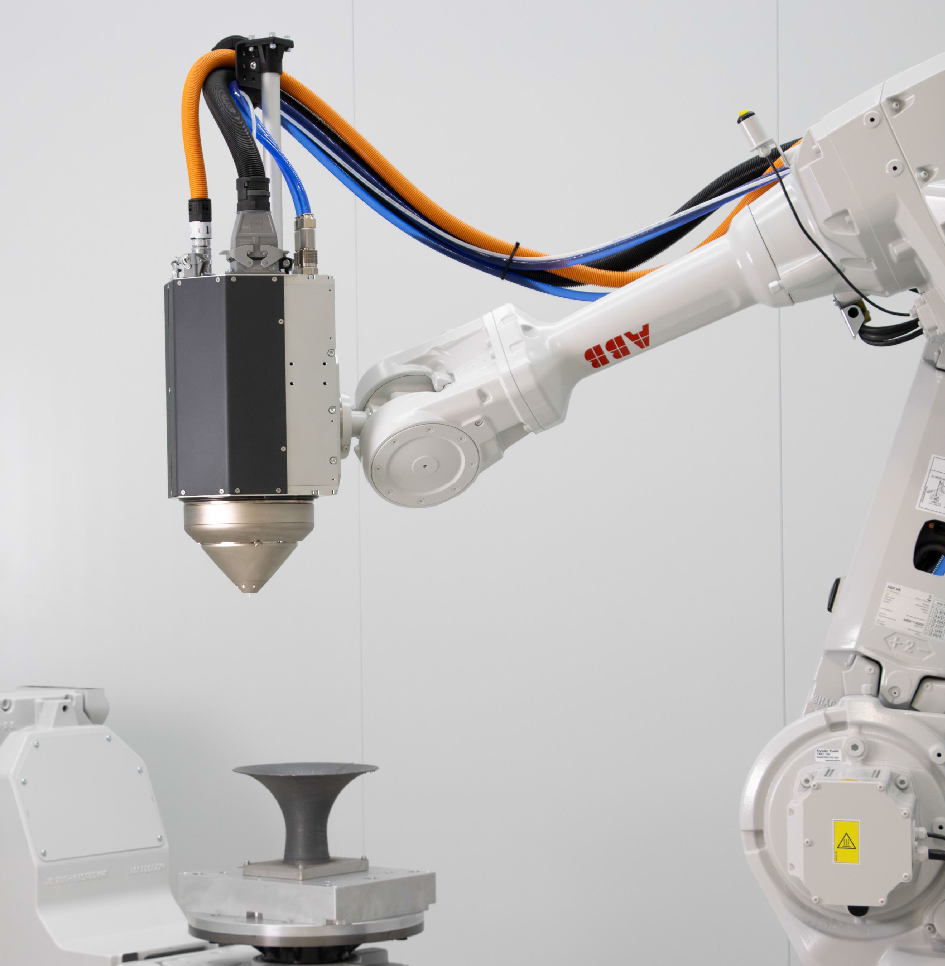

Engine Integration

AM Solutions offers a turnkey robotic metal 3D printing solution based on the Meltio Engine. This fully integrated system includes optimized hardware configuration, software, and process parameters tailored to the customer’s operating environment, enabling immediate use upon installation.

- Single Robot Type

- Hybrid Type

- Mobile Cell Type

- Industry-Specific Chamber Solutions

All-in-one metal 3D printing solution

IR Laser

Blue Laser

Customized systems tailored to each industry

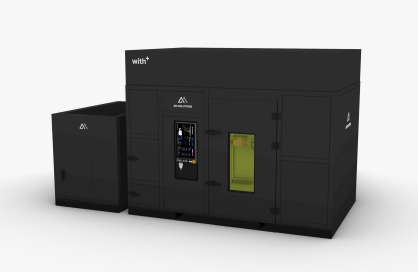

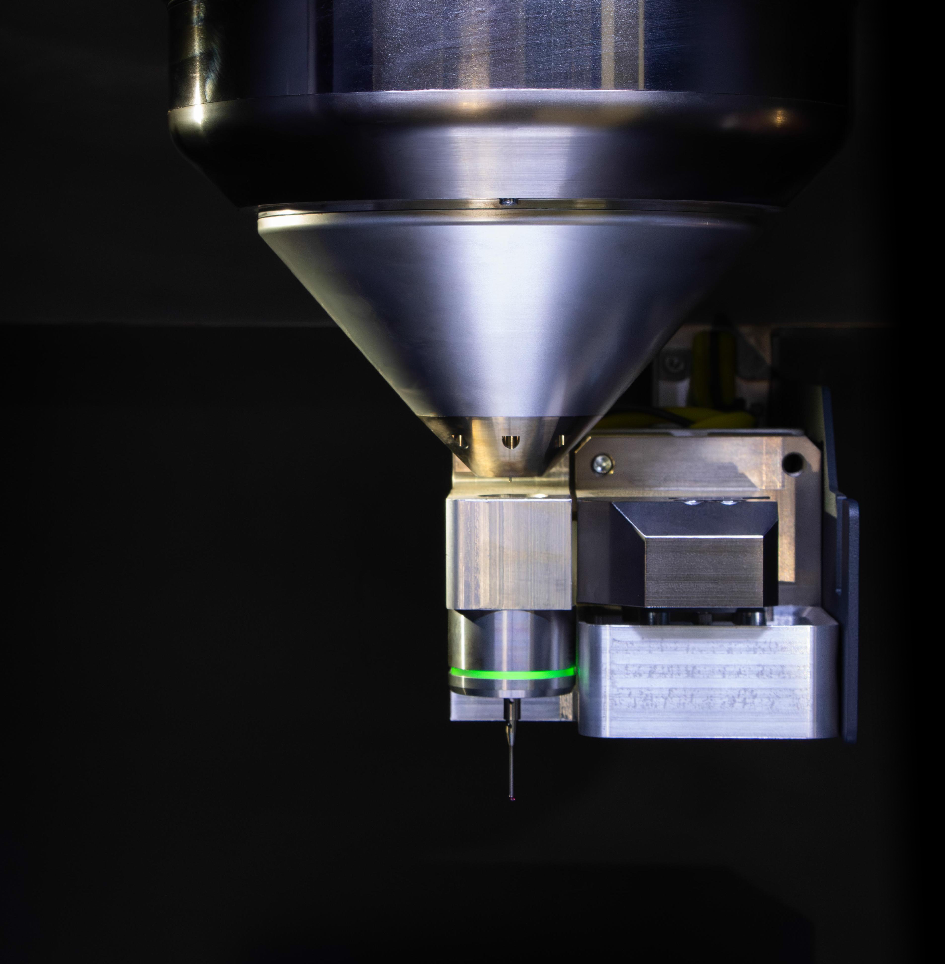

This is a next-generation industrial metal 3D printer designed to meet the advanced metal additive manufacturing needs of industrial sites. Based on Meltio’s proprietary laser wire DED technology, it enables the fast and precise deposition of high-density metal parts in a single process.

While maintaining the simplicity and user-friendliness of the original M450 model, it offers a larger build volume, enhanced structural rigidity, and high-precision motion control — delivering the performance and durability required in real production environments.

equipped with a high-power blue laser source, a large build volume, and a fully inert atmosphere chamber.

- Expanded Build Volume

-

· 300 x 400 x 600 mm workspace

· Capable of producing medium to large metal parts

· Enhanced productivity

- High-Reflectivity Material Deposition

-

· Capable of printing high-reflectivity materials such as copper and aluminum

· Enables production of parts with excellent mechanical properties

- High-Density Wire-Based Deposition

-

· Efficient wire feeding system

· Provides 99.9% material utilization and stable processing

- Enhanced process control algorithms and high-resolution sensor-based monitoring system

-

· Precise control of variables (temperature, melt pool, wire feed stability, etc.) through real-time status feedback

· Long-duration continuous operation process ensures repeatability and quality stability.

| Category | M450 | M600 | Engine (IR) | Engine (Blue) |

|---|---|---|---|---|

| Equipment Type | Industrial Standalone System | Industrial Standalone System | Modular DED Engine | Modular DED Engine for High-Reflectivity Materials |

| Installation Environment | Laboratory, Small-scale Lab | Production Site, Mid-size Manufacturing Line | Robot/CNC Integrated | Robot/CNC Integrated |

| Deposition Method | IR Laser + Wire | Blue Laser + Wire | IR Laser + Wire | Blue Laser + Wire |

| Laser Power | Up to 1.2kW(IR) | Up to 1.4kW(Blue) | Up to 1.2kW(IR) | Up to 1.4kW(Blue) |

| Build Size (XYZ) | 150 x 170 x 425mm | 300 × 400 × 600mm | Platform Dependent | Platform Dependent |

| Dissimilar Metal Deposition (Dual Wire) | Supports Dual Wire | Supports | Supports | Supports (with enhanced precision control) |

| Integrated Control Platform | Meltio Horizon | Meltio Horizon | External System Integration + SPACE | External System Integration + SPACE |

| Integration Target | Standalone Use | Standalone Use | Robot, CNC | Robot, CNC |

| Key Advantages | Compact, Cost-effective, Simple | Blue Engine Technology Built-in, Production-optimized Deposition | High Integration and Modularity | Optimized for High-Reflectivity Metals like Copper and Aluminum |

| Application Areas | Research, Prototype Production | Production of High-Precision Metal Parts | Automotive Lines, Repair | High-Performance Material Deposition, High-Precision Hybrid Part Manufacturing |

| M450 | 구분 | M600 |

|---|---|---|

| 산업용 독립형 시스템 | 장비 유형 | 산업용 독립형 시스템 |

| 연구실, 소규모 실험실 | 설치 환경 | 생산현장, 중형 제조라인 |

| R 레이저+와이어 | 적층 방식 | Blue 레이저+와이어 |

| 최대 1.2kW(IR) | 레이저 출력 | 최대 1.4kW(Blue) |

| 150 x 170 x 425mm | 빌드 사이즈(XYZ) | 300 × 400 × 600mm |

| Dual Wire 지원 | 이종 금속 적층 (Dual Wire) |

지원 |

| Meltio Horizon | 통합 제어 플랫폼 | Meltio Horizon |

| 단독 사용 | 통합 대상 | 단독 사용 |

| 소형·경제성·간편성 | 대표 장점 | Blue Engine 기술 내장, 생산용 적층 최적화 |

| 연구용, 시제품 제작 | 적용 분야 | 생산용 고정밀 금속 부품 제조 |

| Engine (IR) | 구분 | Engine (Blue) |

|---|---|---|

| 모듈형 DED 엔진 | 장비 유형 | 고반사성 대응 모듈형 DED 엔진 |

| 로봇/CNC 통합형 | 설치 환경 | 로봇/CNC 통합형 |

| IR 레이저+와이어 | 적층 방식 | Blue 레이저+와이어 |

| 최대 1.2kW(IR) | 레이저 출력 | 최대 1.4kW(Blue) |

| 플랫폼 종속 | 빌드 사이즈(XYZ) | 플랫폼 종속 |

| 지원 | 이종 금속 적층 (Dual Wire) |

지원(정밀 제어 향상) |

| 외부 시스템 연동+SPACE | 통합 제어 플랫폼 | 외부 시스템 연동+SPACE |

| 로봇, CNC | 통합 대상 | 로봇, CNC |

| 높은 통합성·모듈화 | 대표 장점 | 구리·알루미늄 등 고반사 금속 적층 최적화 |

| 자동차 라인, 보수 적층 | 적용 분야 | 고기능 재료 적층, 고정밀 하이브리드 부품 제작 |