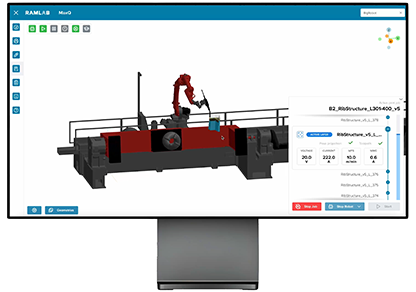

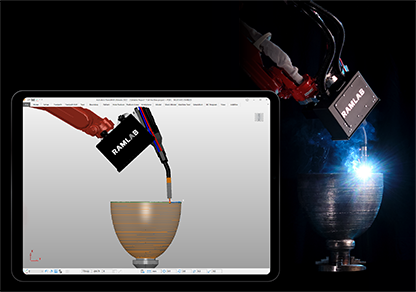

MaxQ 3D Print is a turnkey arc wire system designed for high-quality metal additive manufacturing. It integrates RAMLAB’s proprietary MaxQ 3D Print software and MaxQ Monitoring & Control sensor suite, providing an innovative solution that dramatically improves the reliability and precision of welding-based metal 3D printing.

The system pairs with industrial robots or collaborative robots (cobots) to efficiently produce metal parts of various sizes and shapes.

Integrated metal 3D printing solution

AUTOMATE

YOUR WORKFLOW

- Time is critical in all production processes. MaxQ 3D Print is the epitome of efficiency, capable of 24/7 continuous production. Simply upload the toolpath, set the process parameters, and press start.

- MaxQ 3D Print delivers top-quality welding. It ensures superior weld quality through excellent

- projection software and continuous current and voltage monitoring.

- All data recorded by MaxQ sensors is displayed on a personalized dashboard. Operators can design custom dashboards and set alerts and notifications. Data can be exported as PDFs for training and certification purposes.

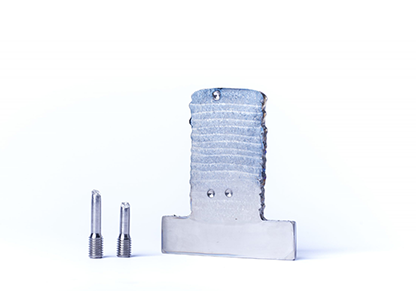

MaxQ Repair is an arc wire system specifically designed for fast and precise restoration of damaged or worn metal parts. By automating the traditional manual repair process, which relies heavily on skilled welders, it improves accuracy, productivity, and cost-efficiency simultaneously.

Based on RAMLAB’s advanced sensor technology and software, MaxQ Repair automatically handles everything from weld path generation to deposition control and process monitoring, enabling high-quality metal part repair even by non-experts.

Automated Arc Wire restoration solution

MaxQ Repair automates the entire defective part repair process in three simple steps.

- SCAN

- Scan the damaged area with MaxQ’s 3D camera to create a detailed digital model.

- PLAN

- Compare the 3D to identify wear and damage, and MaxQ generates the repair toolpath automatically. scan data with the original CAD file

- REPAIR

- MaxQ deposits layers following the generated toolpath, scanning the part before each layer to enable real-time adjustments that maintain accuracy and precision during the repair process.

MaxQ Repair is the most cost-effective solution for metal part restoration.

- Up to 2 times more cost-effective than manual repair

- Up to 3 times faster than traditional methods

- Average ROI of 1.6 years

MaxQ Repair not only restores parts but also strengthens them.

- Consistent repairs with high precision and no human error

- Part lifespan increased by 20% after repair

- Material waste reduced by 42%

MaxQ Repair is designed for ease of use without complex manual repairs.

- No need for skilled welders

- No CAD/CAM programming required

- Users can be trained and operate the system within just a few hours

Cobot

FANUC CRX-10IA

800mm x 400mm x 300mm

Build volume

Fronius or Miller

Weld source

Cobot

TECHMAN TM12

800mm x 400mm x 300mm

Build volume

Fronius or Miller

Weld source

Robot

PANASONIC TL-1800

1400mm x 1000mm x 800mm

Build volume

Panasonic

Weld source

Robot

FANUC CRX-10IA

5000mm x 2000mm x 1500mm

Build volume

Panasonic

Weld source